Our experts believe this year could be the biggest opportunity for forklift safety improvements since awareness of the subject began. In fact, that’s why we’ve sponsored the UK Manual Handling Association’s convention in June and why we passionately support National Forklift Safety Day too.

But what makes 2022 so important? It’s simple: the rise in demand for building, including DIY, materials post-Covid combined with the arrival of innovations like the offset tiller arm make forklift safety both more essential than ever and easier than ever to achieve.

Read on to discover why improving forklift safety in your businesses can’t wait AND explore recommended forklift specification advice from our experts.

Choosing the Right Forklift for Maximum

Sticking with the UK as an example, the Construction Products Association predicted earlier this year that output in its industry would grow by 4.3% in 2022. It added that housebuilding remains key and that “the outlook for volume remains positive, with most major house builders reporting strong near-term demand and healthy profit margins fuelled by demand for housing in affordable areas of the UK”.

Meanwhile, demand for DIY materials has reached unprecedented heights, due to a demand for utility bill-reducing and home office projects, leading to two major UK retailers announcing wage increases for colleagues.

Factors such as these all add up, however, to greater pressures on warehouse performance as well as potentially greater interaction between materials handling and pedestrians and therefore increased opportunities for accidents.

The good news? Forklift design has advanced ahead of this trend and now offers simple, highly effective features you can – and should – review as potential options to reduce the chances of an accident in your warehouse.

By optimising existing storage, you can improve safety, reduce costs, improve environmental impact and address produce damage to make your business safer and more efficient.

Warehouse Planning and Forklift Safety

Any serious warehouse safety review should also consider a warehouse planning analysis for some simple reasons: there are improvements in visibility, materials handling processes and most of all driver fatigue to be found in looking at a warehouse as a ‘big picture’.

A complimentary service using CAD design to find and show the capacity and ideal layout of your facility, a Combilift warehouse analysis will provide layout proposals, site inspection and diagrams to evidence where and how improvements can be made.

The free review includes racking layout proposals and storage density calculations to create the best possible performance from any warehouse and will show how to achieve results like the below and more in safer, smarter ways:

• Direction of travel: Find out more about the clever Combilift approach that enables the operator to change the direction of travel by 90 degrees at the flick of a switch.

- A workplace designed for older operators: Ask how better layout and easier vehicle access can reduce tiredness and injuries as well as make a workplace easier for older colleagues.• Long loads…everywhere: You’ll discover how Combilift can manoeuvre even long loads down narrow aisles, through standard doorways and around obstacles with ease, enabling racking to be placed closer together, reducing the amount of operational space required.

Why Combilift?

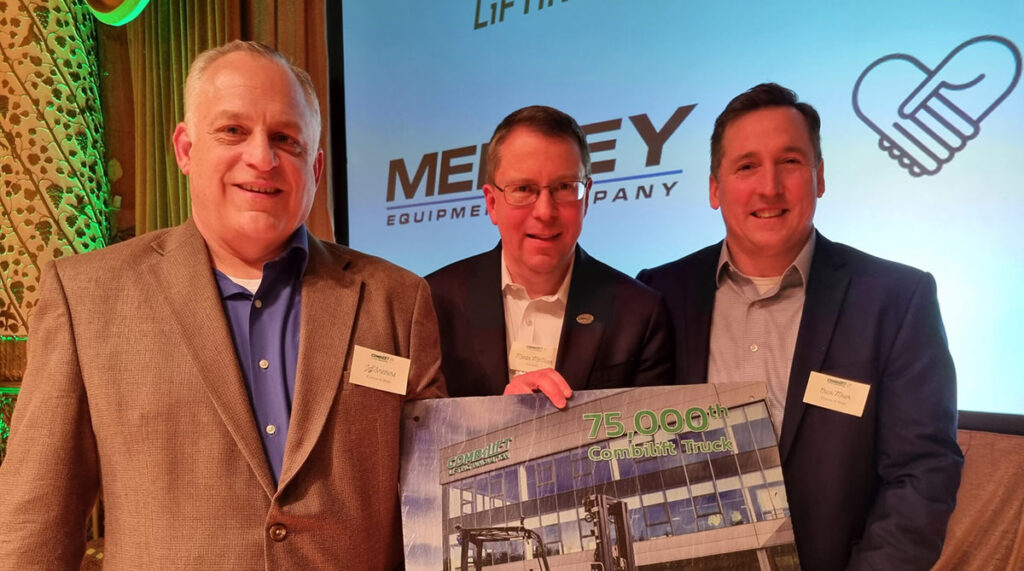

Combilift, an industry-leading manufacturer of multi-directional forklifts, is the world’s fast-growing forklift manufacturer and has exported well over 60,000 vehicles to 85 countries. Plus, our free warehouse planning consulting helps clients to release up to 50% more capacity with improved safety and efficiency in their facility.

We’re proud to say that no other manufacturer in the world can deliver the same level of customisation and adaptability or cater so effectively to the diverse needs of every individual business of any size.