Sustainability

Sustainability

Our commitment to a better future

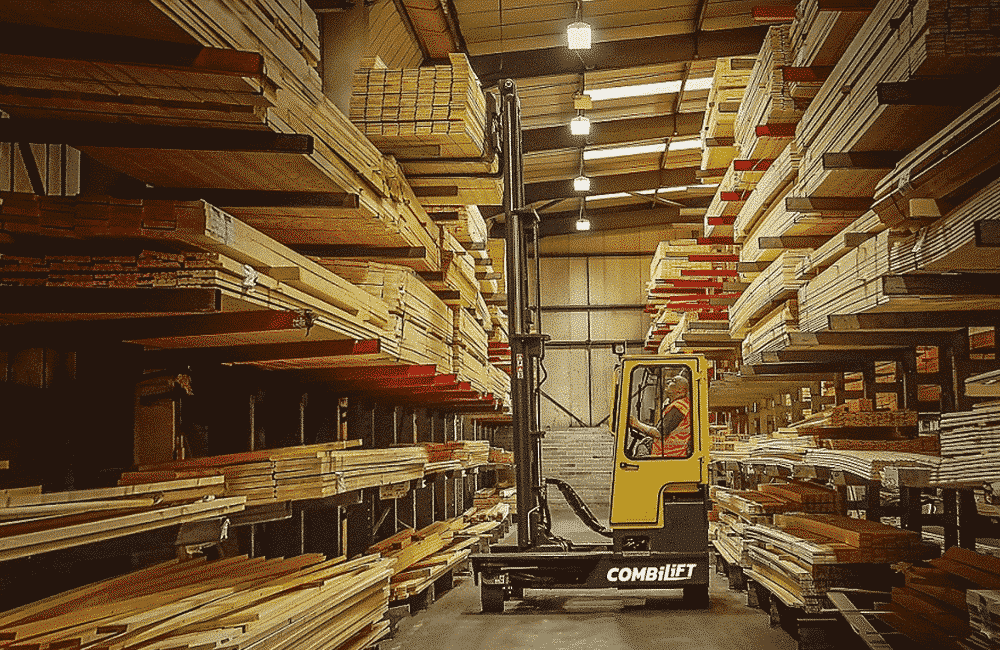

Empowering Our Customers' Sustainability

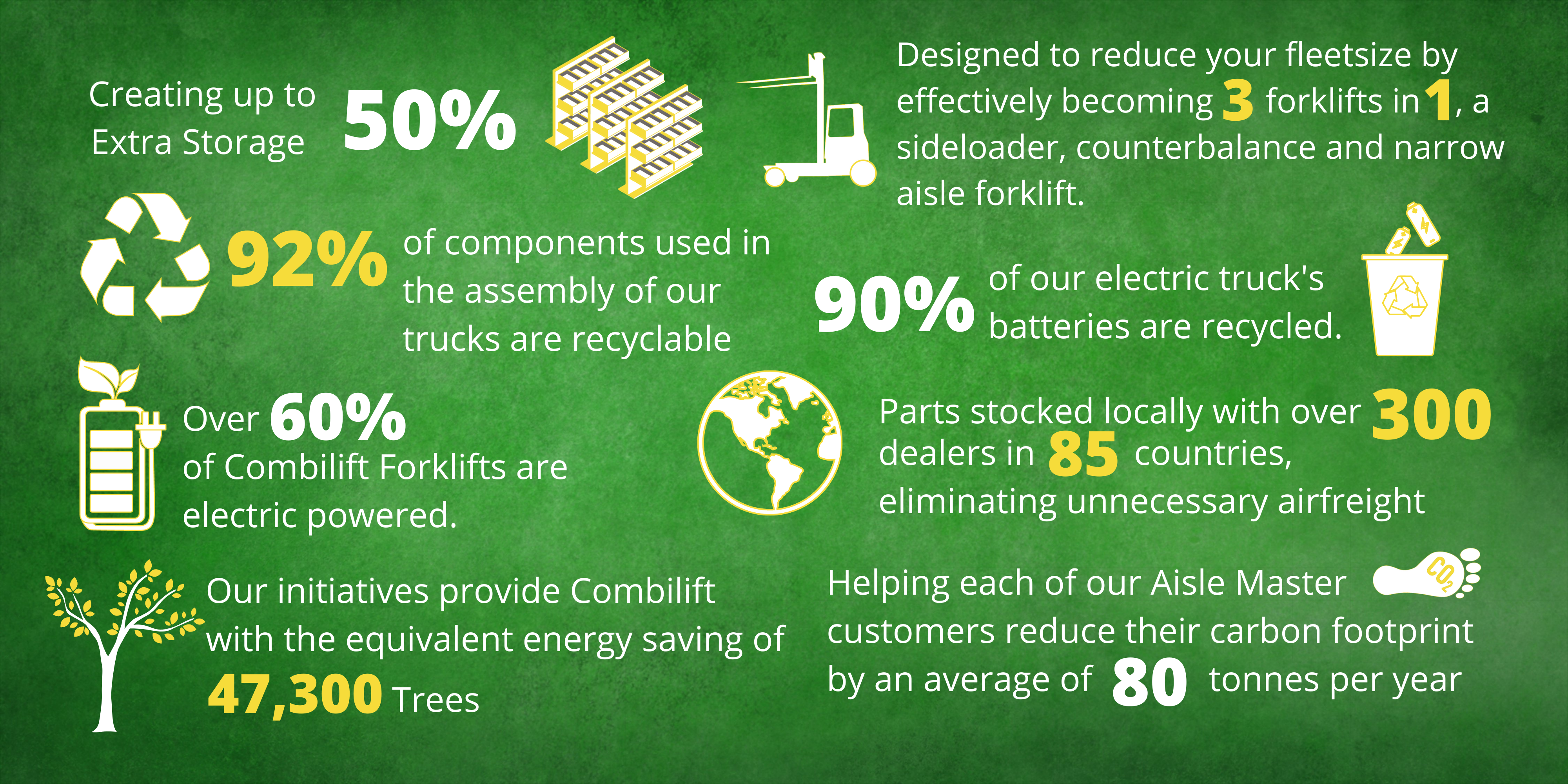

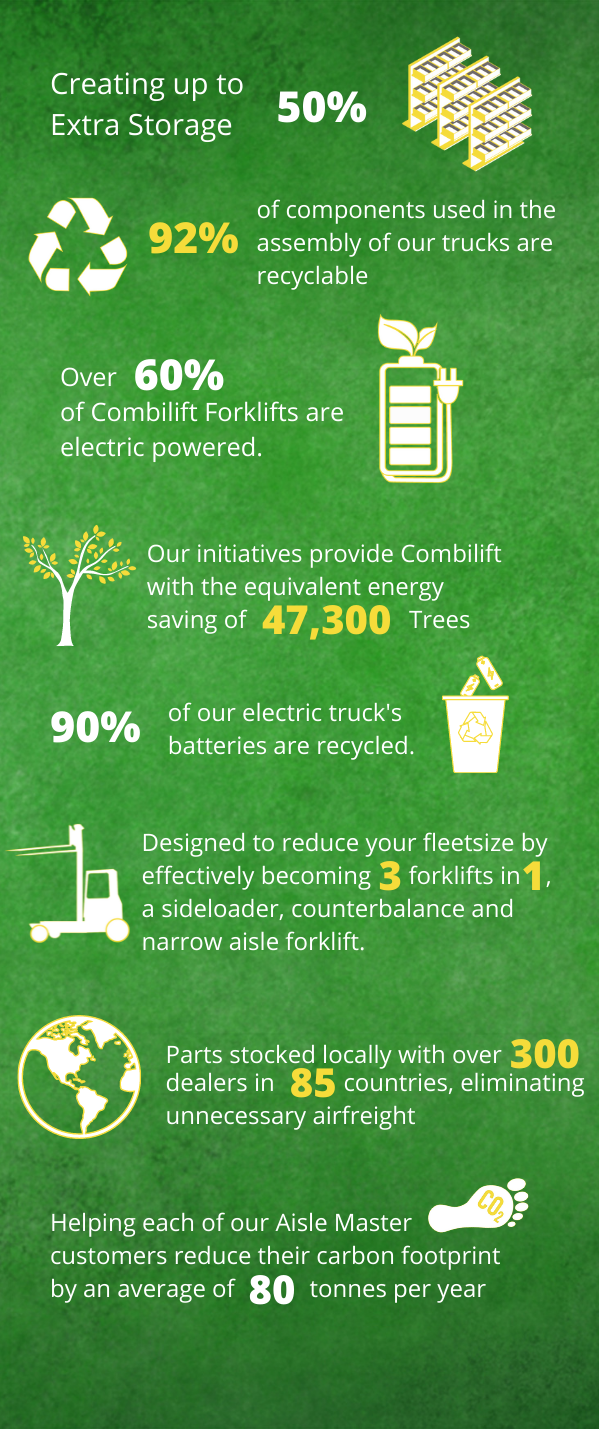

We produce versatile forklift technologies that can fulfil multiple roles, inside and out, reducing fleet size, thus reducing carbon footprint. The carbon footprint can be further reduced by using electric forklifts, and our diesel and LPG engines adhere to the strictest emissions and efficiency guidelines. In addition our solutions are over-engineered to expand the truck’s lifespan and reduce the costs associated with maintenance.

Your Roadmap to Sustainable Warehousing

Combilift's Sustainability Efforts

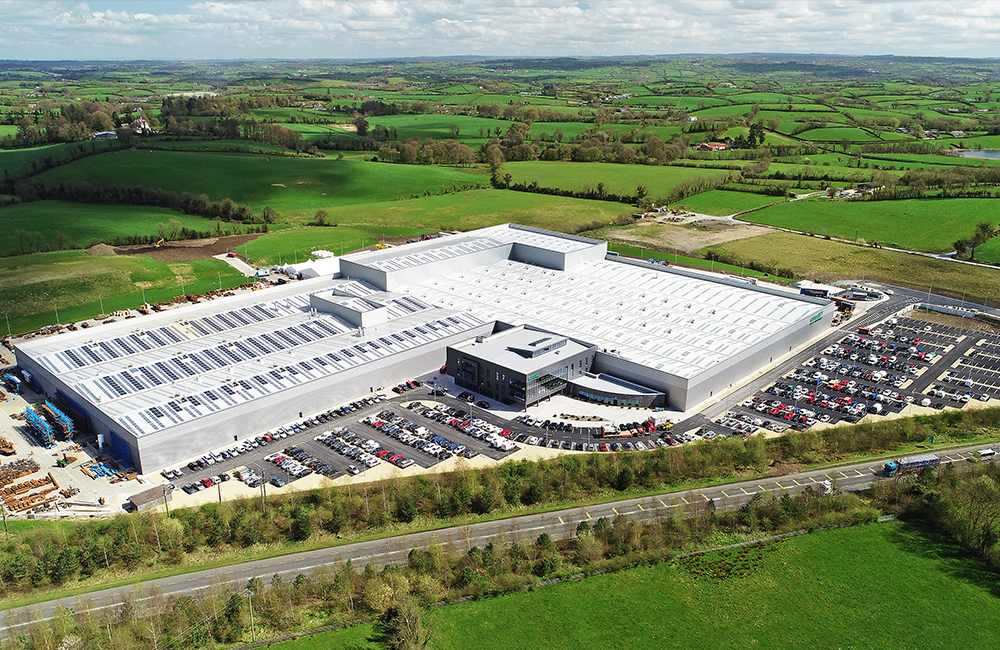

Green Production Process & Facilities

30% of our roof space is covered in skylights, enabling staff to work in natural daylight with 173% more white light exposure creating better employee working conditions.

Daylighting Technology

We use LED lighting with PIR sensor lights allowing for daylight dimming and areas of the factory not in use to be switched off automatically.

LED Lighting

We are using a 1Mw Biomass boiler to reduce our LPG usage in our paint spraying booths and, in turn, generating a saving of 473,316kg of CO2.

Biomass Fuel

We employ solar panels that provide 185kW of energy which generate 10% of our daily electricity usage.

Solar Panel Energy

We have a 110,000-litre rain water collection system is in operation, which is used in jet washing and our plant’s restroom facilities.

Harvesting Rainwater

Employee Development

Our Commitment to the UN Sustainable Development Goals

At Combilift we provide a safe, healthy working environment for everyone. We aim to achieve zero injuries through initiatives such as our safety barriers separating our 600+ employees from moving vehicles and by encouraging our employees to submit routine safety observations through our “Good Catch” program.

We provide quality education and the opportunity to elevate the career potential of many through programs such as our fully funded OEM Engineering Technology Traineeship & Apprenticeship, preparing a large number of individuals for work as future Engineers or Technicians.

At Combilift, we work hard to help warehouses get the most out of their cube utilisation. We promote the optimisation of storage in developing resilient infrastructures and foster innovation to help our customers help improve their energy efficiency and reduce their CO2 emissions.

We strive to guarantee green procurement patterns through our supplier qualification process and ensure sustainable manufacturing practices at our state-of-the-art production facility. For example, by using water-based paints, we cut our VOC emissions by 73%.

Through our Global collaboration with Brazil, we deliver lifesaving equipment to multiple patients in developing countries with our Combi-Ventilate that converts one ventilator into several ventilation stations. As a result, we are ensuring everyone’s health and well-being during the Covid-19 crisis.

At Combilift we provide a safe, healthy working environment for everyone. We aim to achieve zero injuries through initiatives such as our safety barriers separating our 600+ employees from moving vehicles and by encouraging our employees to submit routine safety observations through our “Good Catch” program

3. Good Health and Well-Being

We provide quality education and the opportunity to elevate the career potential of many through programs such as our fully funded OEM Engineering Technology Traineeship & Apprenticeship, preparing a large number of individuals for work as future Engineers or Technicians.

4. Quality Education

At Combilift, we work hard to help warehouses get the most out of their cube utilisation. We promote the optimisation of storage in developing resilient infrastructures and foster innovation to help our customers help improve their energy efficiency and reduce their CO2 emissions.

9. Industry, Innovation

and Infrastructure

We strive to guarantee green procurement patterns through our supplier qualification process and ensure sustainable manufacturing practices on our state-of-the-art production line. For example, by using water-based paints, we cut our VOC emissions by 73%.

12. Responsible Consumption &

Production

Through our Global collaboration with Brazil, we deliver lifesaving equipment to multiple patients in developing countries with our Combi-Ventilate that converts one ventilator into several ventilation stations. As a result, we are ensuring everyone’s health and well-being during the Covid-19 crisis.