Lumber Yard Efficiency is No Longer Optional! Here’s Why

Our materials handling experts are always proud to boost efficiency (and capacity!) for lumber yard owners BUT they’ve been seeing a growing trend lately: lumber yard professionals needing urgent help to improve their yard.

This is why: factors like the rising costs of raw materials, the need for electric forklifts and a lack of a shared system between yards mean an ultra-efficient but safe operation can’t wait any longer.

After all, damage to stock and lost time not to mention losing out to competitors on sustainability and generally poor processes are no longer affordable in 2022.

We asked our specialists for their must-see lumber yard efficiency advice as well as details of some common, costly errors they’ve been seeing…

Lumber Yard Efficiency: Capacity, Capacity, Capacity

It’s simple: rising transport costs, challenges sourcing raw materials and increased demand from some customers will increasingly mean one thing: capacity is everything for a lumber yard.

Yes, efficiency, sustainability and safety are absolutely essential factors but achieving greater capacity should be the goal of every part of an improvement plan.

Thankfully the available ways of doing this are very straightforward, so this blog will look at:

- Better (and fewer) materials handling trucks: Using enhanced truck features, such as multipurpose capacity and longer battery life, is a key step to better results.

- Better yard layout: A properly analysed and executed layout means easier, quicker and safer access to the right materials at the right time with less damage.

- Better processes: Delivered as part of a yard layout assessment, simple and effective processes for an improved operation will deliver BIG when scaled across the months and years.

Click here to find out how a free layout consultancy service, including 2D and 3D visuals produced for you at no charge, can unlock up to 100% extra storage cost without the need for additional warehousing.

Lumber Yard Efficiency: Better Trucks (and Common Errors)

Some of the errors our experts are seeing, when it comes to choice of forklift for their yard, are errors lumber yard operators can no longer afford to live with.

We’ve recently helped result issues with:

- Damage to raw materials: Increased efficiency will, by design, reduce product damage. The wrong choice of truck means, without the capacity to block stack and drive sideways, contact with other stock becomes harder to avoid. Also, too narrow a machine means more risk of bowing or damaging the wood.

- Too many vehicles: The unnecessary use of multiple machines simply adds further danger or bowing or damage. Our recommended truck (see below) as a first go-to is designed for indoor and outdoor use meaning fewer vehicles and reduced damage risk.

- Poor handling abilities: We’ve seen problems like trucks with poor battery and small format twin wheels being used plus lack of multi-directional operation and side loading capacity.

Our specialists recommend that lumber yard professionals assess the C-Series multidirectional forklift and the Combi-SL sideloader forklift truck. Thanks to its long load capacity, outdoor-capable tyres and long battery run time the Combilift XLE 5,000kg capacity multidirectional forklift is a must-see.

Lumber Yard Efficiency: Better Yard Layout

Aside from the issue of capacity mentioned above, the easiest possible access to the materials you need when you need them is no longer optional for a modern lumber yard.

Our video shows the problems a yard can experience when reaching the right stock, made worse by the use of an unsuitable truck, and the obvious safety and efficiency problems this causes. It’s worth repeating again that such issues are no longer affordable for lumber yards.

Layout has also become a vital consideration as sourcing additional warehousing space is becoming more expensive and it is, by its nature, a finite resource!

Find out here why maximizing the warehouse footprint you do have can be a big part of your sustainability plans.

Lumber Yard Efficiency: Better Processes

We’ve seen more and more demand from across the world for Combilift’s layout expertise and innovative materials handling vehicles. As well as the US, the UK and Scandinavian countries in particular are investing in better lumber yard processes.

Ultimately, at a time when most costs, some supply chains and customer budgets are all under pressure the need to improve margins while reducing loss has never been more pressing.

A recent Markets Insider assessment of the climate for the price of raw materials – especially, of course, the price of lumber – reports that the “scorching rise in lumber prices last year hasn’t been able to continue in 2022” but warns “this year still holds the potential to see prices rise back to the $1,000 mark as demand for the building material perks up within a tight supply market”.

The report concludes that:

- Lumber prices are down more than 20% this year in 2022 but are set to rise again.

- Futures pricing for lumber suggests an increase in summer demand.

- Higher interest rates have dampened demand in the UK housing market so far in 2022.

There’s never been a better time to review your warehouse processes to make sure efficient, safe and sustainable materials handling is a minimum standard in your yard.

Lumber Yard Efficiency: How We Can Help

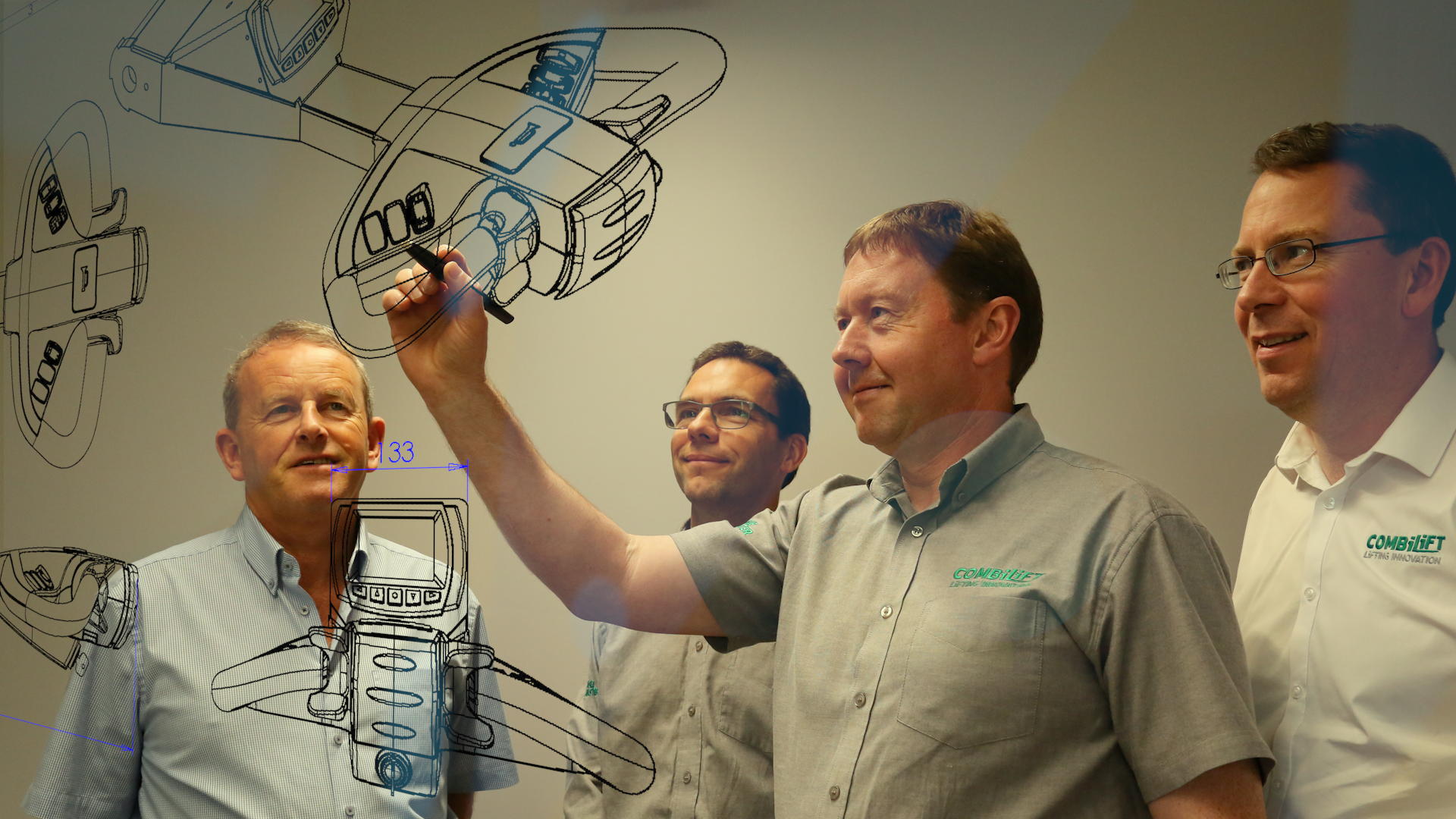

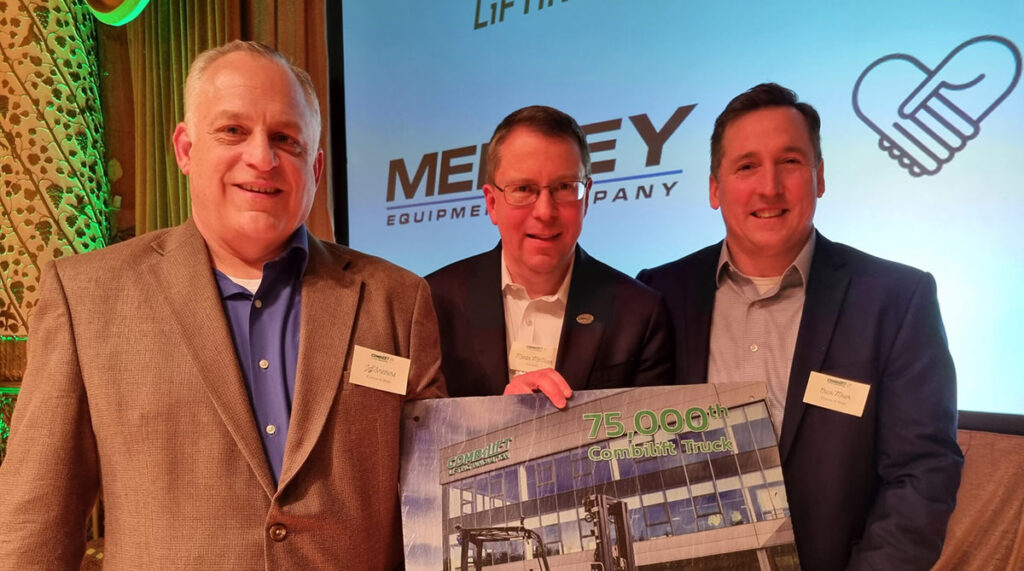

Our specialists are renowned worldwide for their lumber yard efficiency know-how. After all, Combilift is the largest global manufacturer of multi-directional forklifts and an acknowledged leader in long load handling solutions.

For example: In Austria Combilift was named Timber Trade Supplier of the Year by leading publication Holzkurier.

Exporting to more than 85 countries and with more than 60,000 trucks in use worldwide, no other manufacturer in the world can deliver the same level of customization and adaptability or cater so effectively to the diverse needs of every individual customer.

To find out how Combilift can deliver a quicker, safer materials handling capability in your lumber yard, with enhanced storage capacity and superb RoI, simply contact a Combilift specialist for expert advice or to request your free layout consultation.

Book you free warehouse service today!

Increase Space, Improve Efficiency and Save Money with our free site optimisation service. Simply tell us a little about yourself and your facility. Then upload your site plan. Our team of optimisation experts will help you get the most from your storage facility.